Support Tools for New Product Development

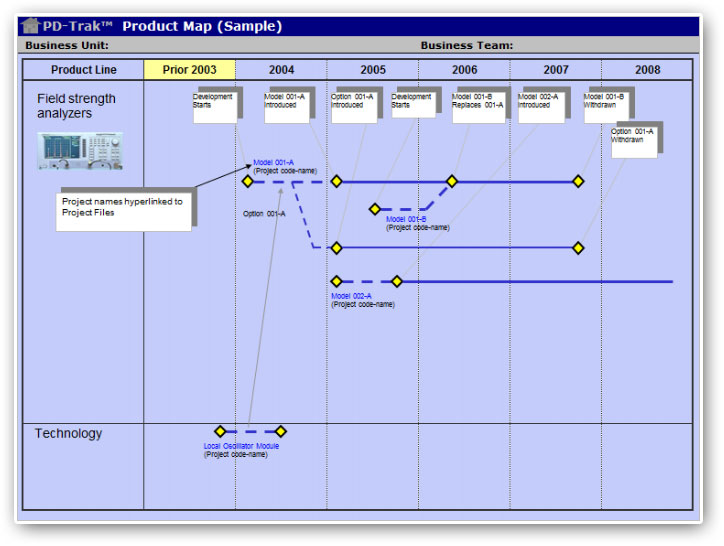

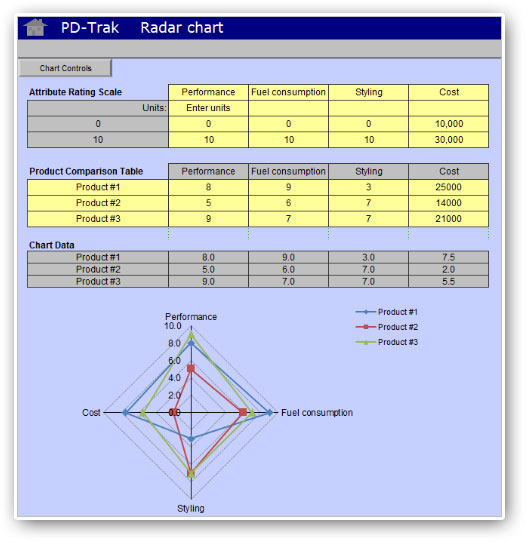

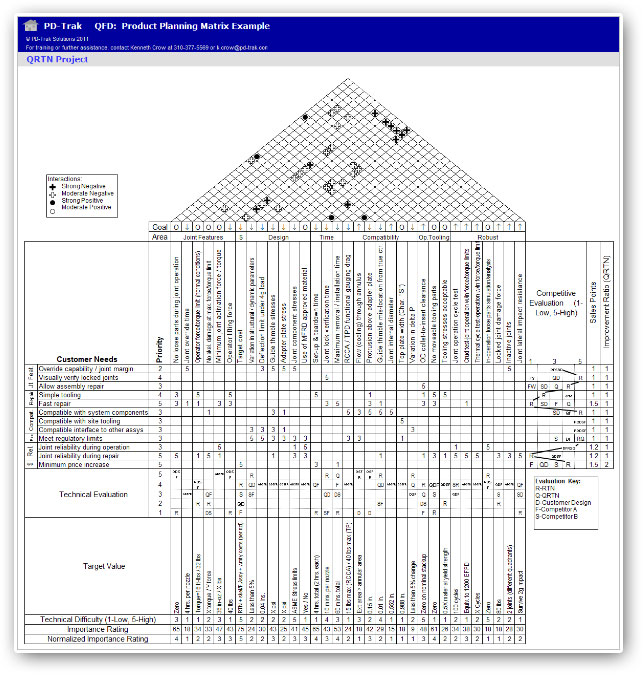

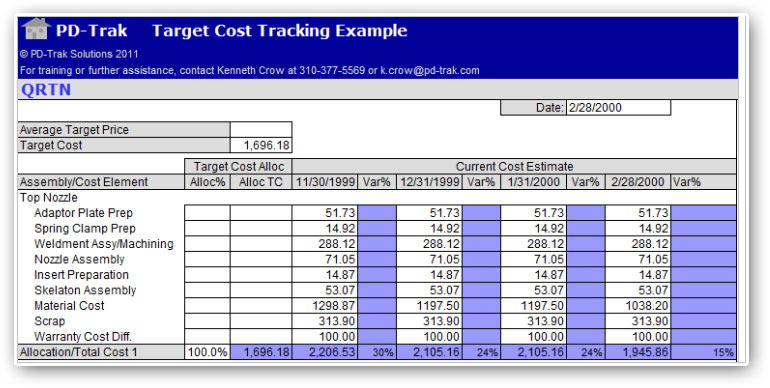

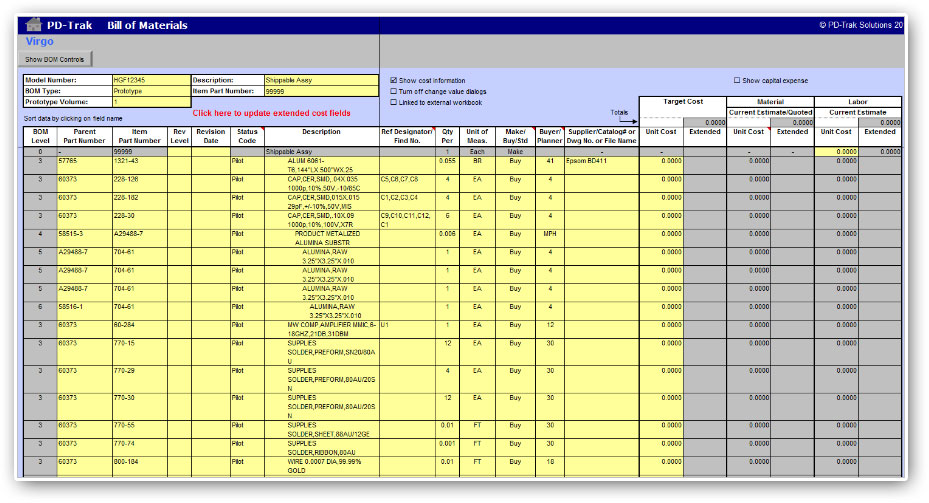

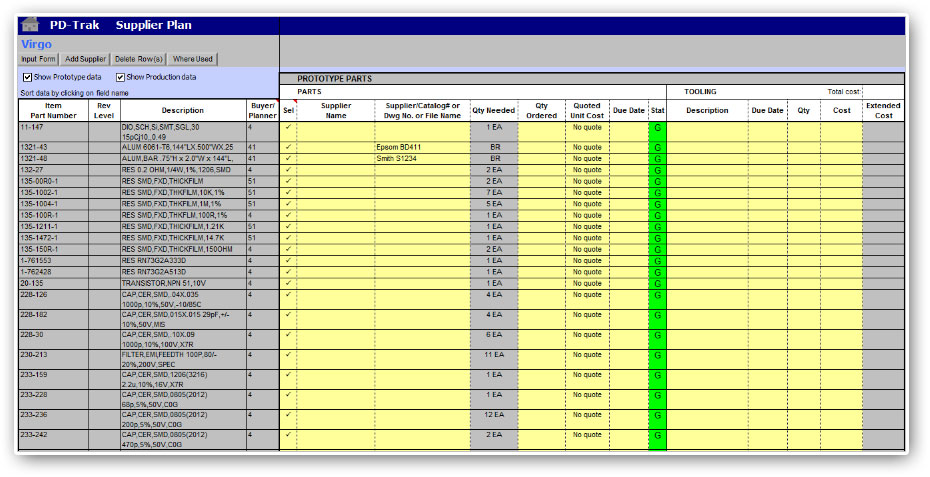

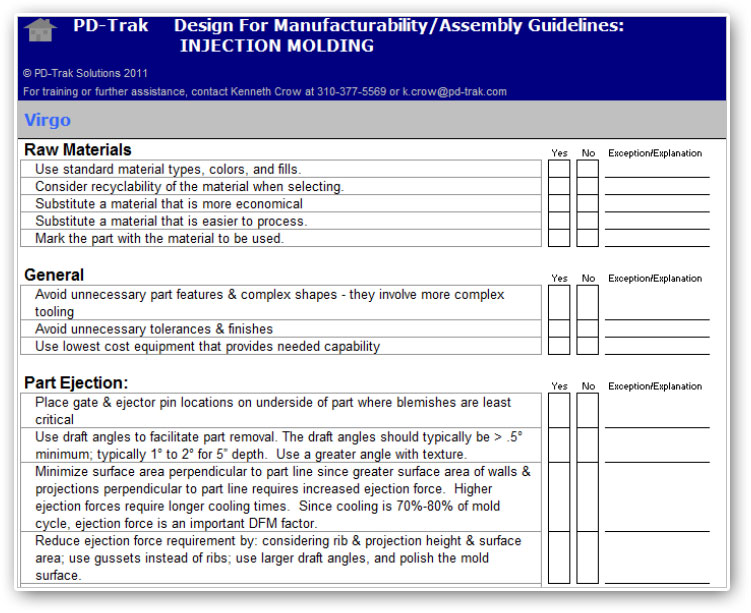

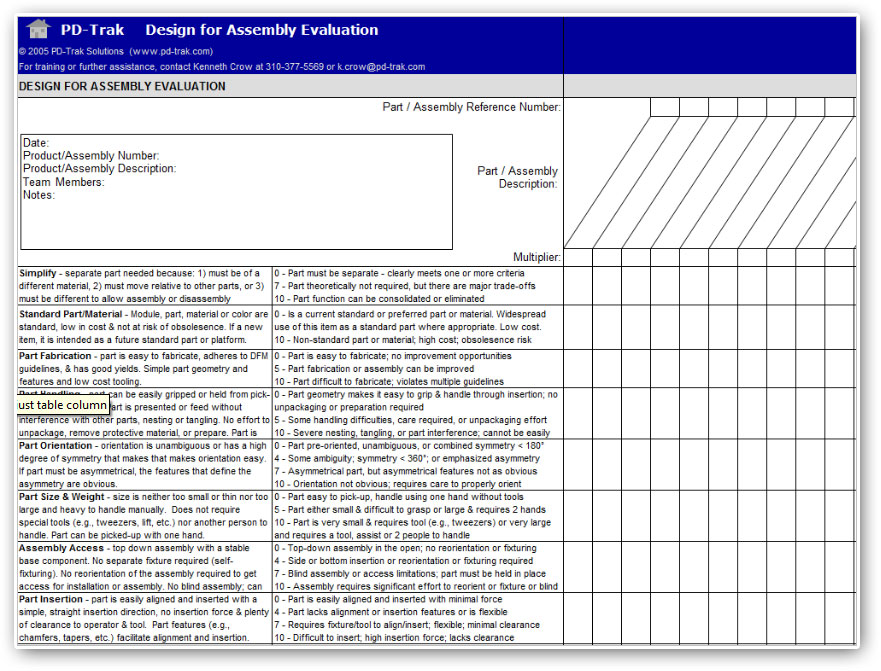

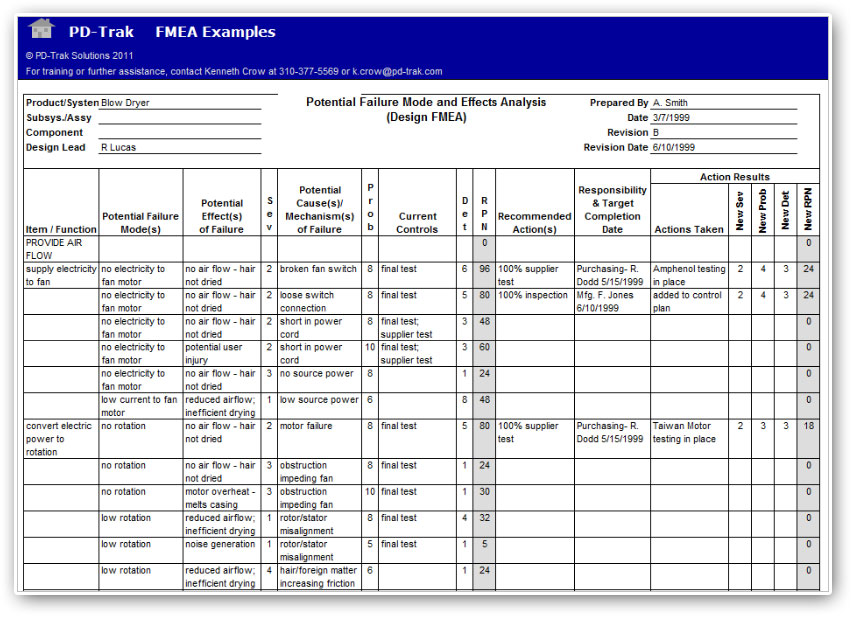

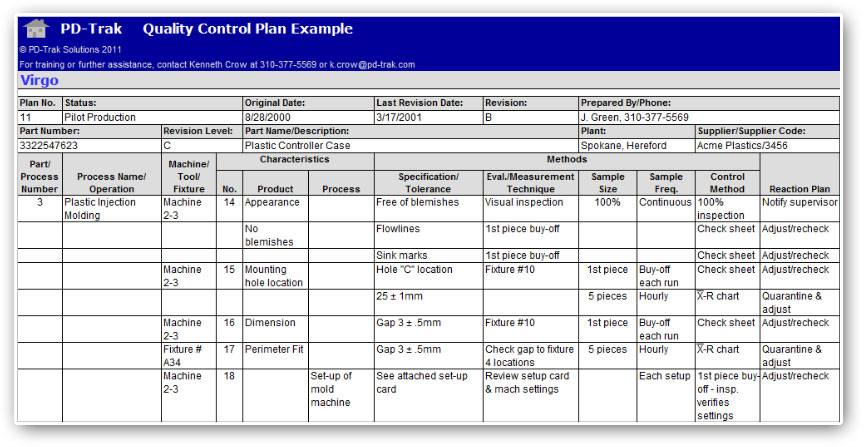

PD-Trak provides a range of tools to support different aspects of new product development. These downloadable tools are Microsoft Excel® based. The tools include three elements: 1) instructions that describe the methodology and how to use the tools, 2) an example of the tool that has been completed, and 3) a template for the tool. These tools include the following.